Vision is our main sense for gaining information on the shop floor, which is why manufacturers lean on visual systems for their operators.

However, not all visual systems are equal.

In the first example, visual signage is used but this is NOT a visual system.

The visual sign is there but it requires the operator to take time and count the pallets.

Introducing a ‘not above the line’ mark as seen in example 2, provides a simple visual system.

This is a much more efficient system making it obvious to the operator, which in turn speeds up processes and reduces error.

When installing visual systems, it is important to ensure that they are simple and obvious as possible. This should be applied to work instructions and presenting important data to your team to reduce mistakes and improve efficiency.

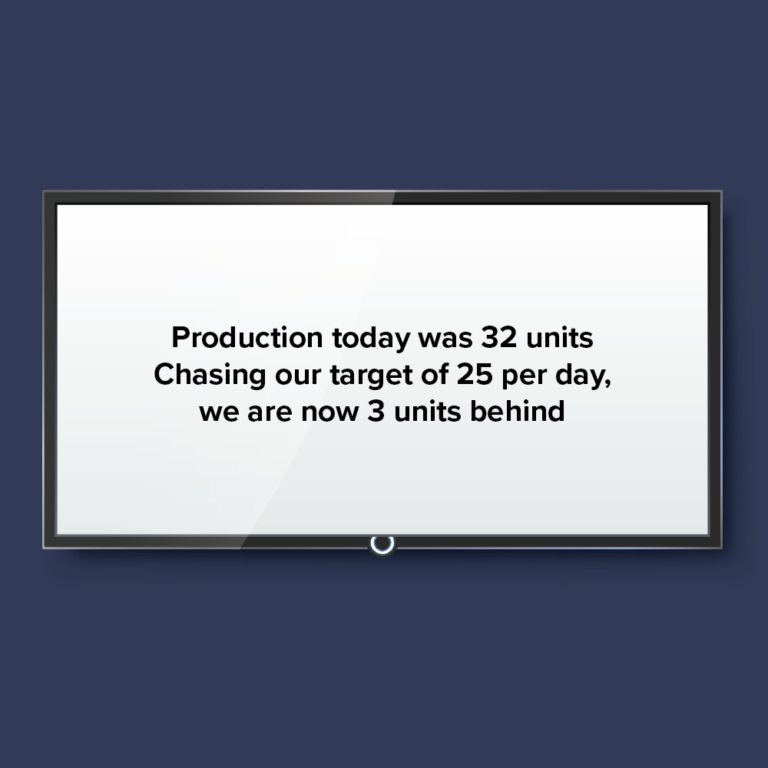

Take a look at the image on the left where you will see a shop floor dashboard with some key performance indicators. It tells the Operators the information that they need but it is so small and insignificant that they are likely to miss it.

In just 3 steps, we can turn something that is unnoticed into something that is easy to understand and take on board:

Step 1: Eliminate the clutter and make it much bigger Get straight to the point by taking out any unnecessary words and making everything much bigger

Step 2:Use alignment Put everything in columns to make it easier to interpret

Step 3: Use colour to indicate where they are at Colours make the information pop and can motivate Operators

NoMuda VisualFactory transforms manufacturing processes into a visual system to increase efficiency and reduce waste. This ranges from dynamic, digital step-by-step work instructions to visual dashboards to display your KPIs as seen above.

Rhopoint Instruments’ Managing Director, Tony Burrows, has really noticed a difference in the way his team works with NoMuda VisualFactory.

“Each Workstation is equipped with a vScreen, displaying digital work instructions that provides the operators with visuals to identify the tools and bin location. VisualFactory has been really useful for us and has allowed us to improve productivity and grow without expanding our workforce.”