Home / MES VisualFactory / Features & Benefits

Digital Standard Work Processes

Production engineers can now develop digital work instructions for the shop floor operators to help improve manufacturing efficiency and product traceability. Using NoMuda MES Visual Factory, production engineers set up digital work instructions that are shown to the operators on computer screens or mobile devices. The screens follow a standard format so the operators know where to find the relevant information and can focus on the task at hand.

Intuitive User Interface and User Experience

The user interface and the user experience of VisualFactory is designed for the shop floor operators. Operators are shown step-by-step digital work instructions to complete a specific task.

Visual Factory UI/UX includes:

- Standard screen layout to ensure consistency of work instruction presentation.

- UI incorporates all the information required: components, tools, checks, warnings, drawings, videos, etc.

- Focused screens that only show the specific task at hand to simplify the presentation

- Integration with external dependencies to remove the requirement for manual checks, ex scan part numbers instead of manually entering them for verification.

- Web based screens that are accessible from any web browser, including mobile phones, tablets and touch screens.

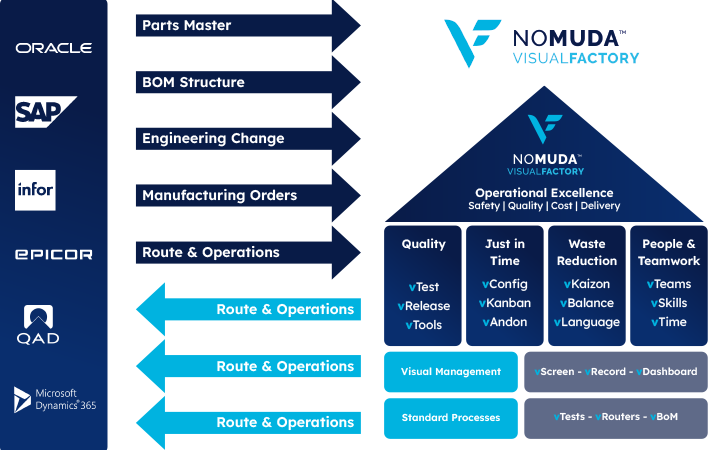

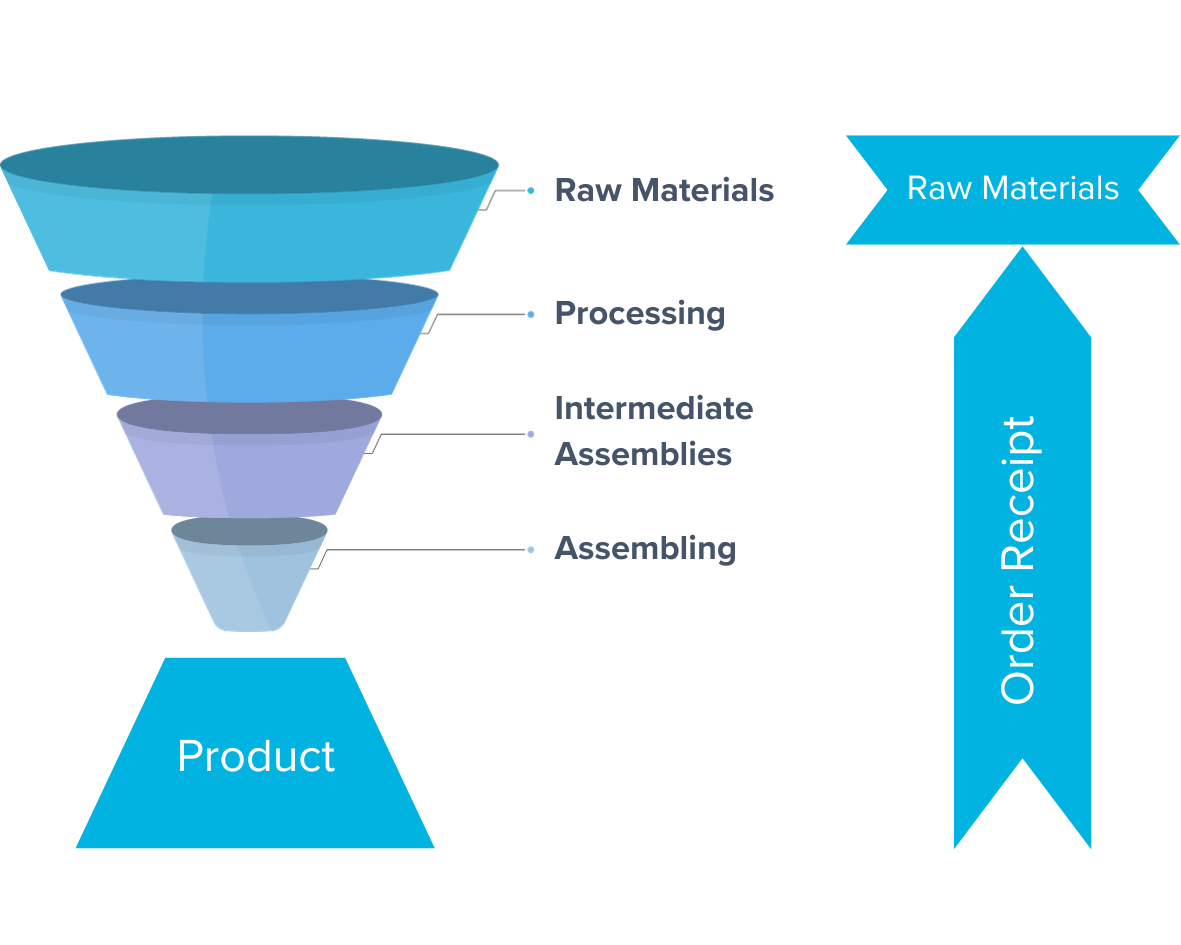

Flexible Work Order Processing to Support Complex Product Configuration

Manufacturing companies that have a high degree of product configuration during their ordering process require a flexible manufacturing process. VisualFactory enables thousands of product variants to be manufactured from a single set of digital work instructions. Production engineers are able to pre-define the different variants that will automatically generate the correct digital work instructions based on a product definition. This simplifies the process of defining standard work instructions in an environment that has a high degree of product configuration during the ordering process. At the core of Visual Factory is a rules engine that allows production engineers to setup different variants and options based on the following inputs:

- Parts: if a product has a different Bill of Materials, VisualFactory will show the correct parts for the correct variants.

- Process: if a product has a different process steps, VisualFactory rules engine will identify the correct steps for the selected variant.

- Parameters: if a product requires different measurements or values, Visual Factory will show the correct values for the selected variant.

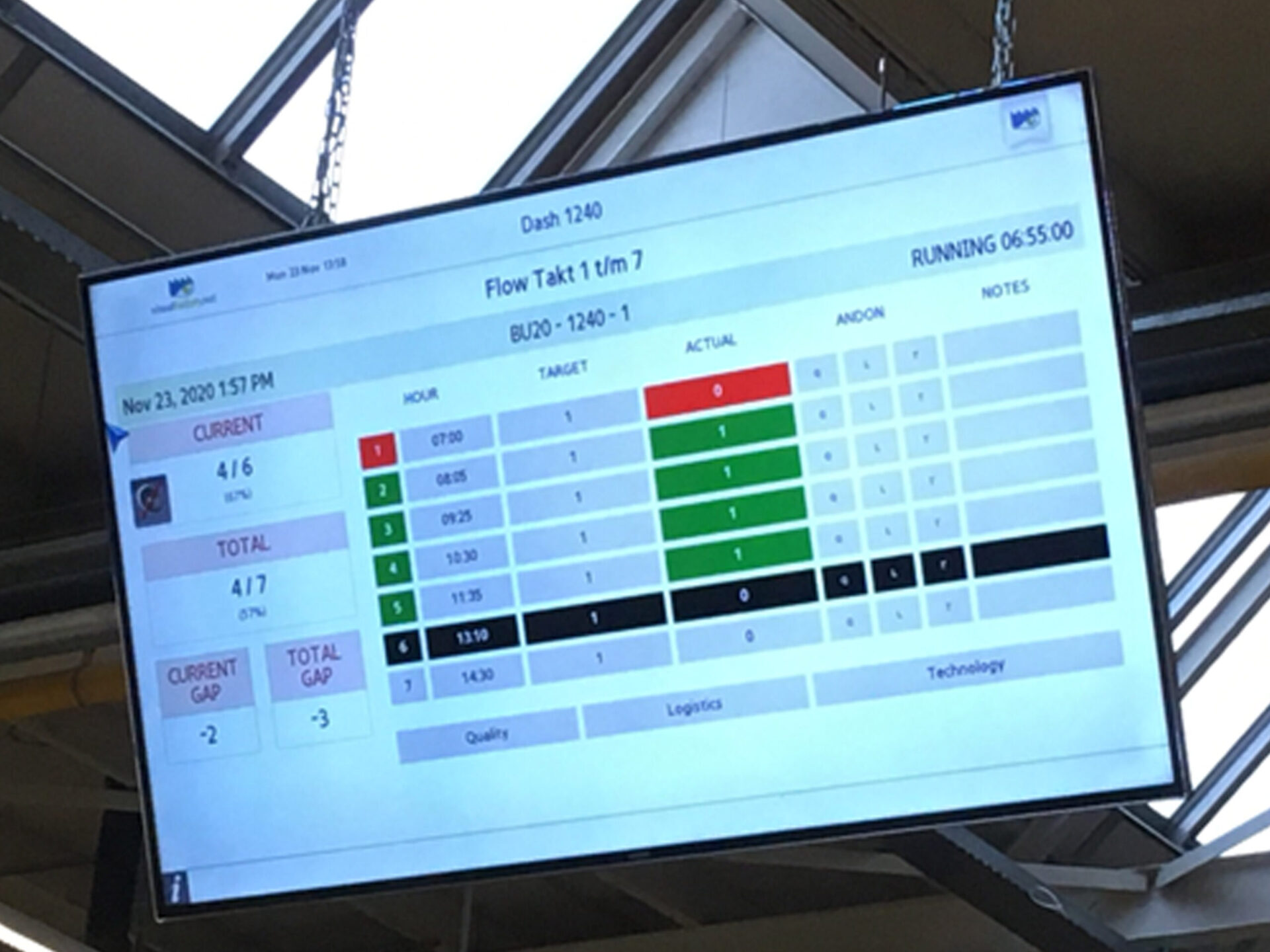

Real-time Management Reports and Dashboards

Using data to make better decisions that help to increase manufacturing efficiency is a management priority. Visual Factory records all the events taken during the manufacturing process to allow managers access to factory floor data. Managers can now get real-time answers to questions like:

- How many did we produce today

- How many labor hours were required

- What stoppages occured

- What is the First Pass Yield

- Which staff are trained to work on a particular station

- What is the mean difference in cycle time between Products A & B

Digital Product Traceability for Audit Compliance

To help improve manufacturing efficiency, Visual Factory simplifies the process of audit compliance since all the steps of the manufacturing process are recorded. Visual Factory can create a complete manufacturing history for every product that was built in the factory. A 'Digital Birth Certificate' is available that includes:

- steps used in the manufacturing process

- date and time required for each step

- operator responsible for each step

- relevant settings

- list of parts and description

This single source of information removes the cost of manually recording each step on paper and then scanning the paper for archival purposes.

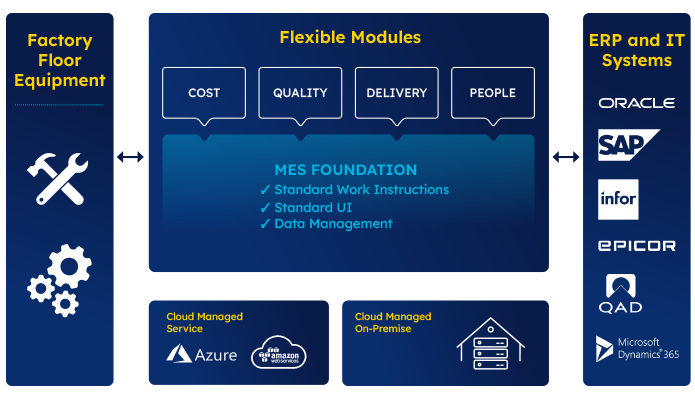

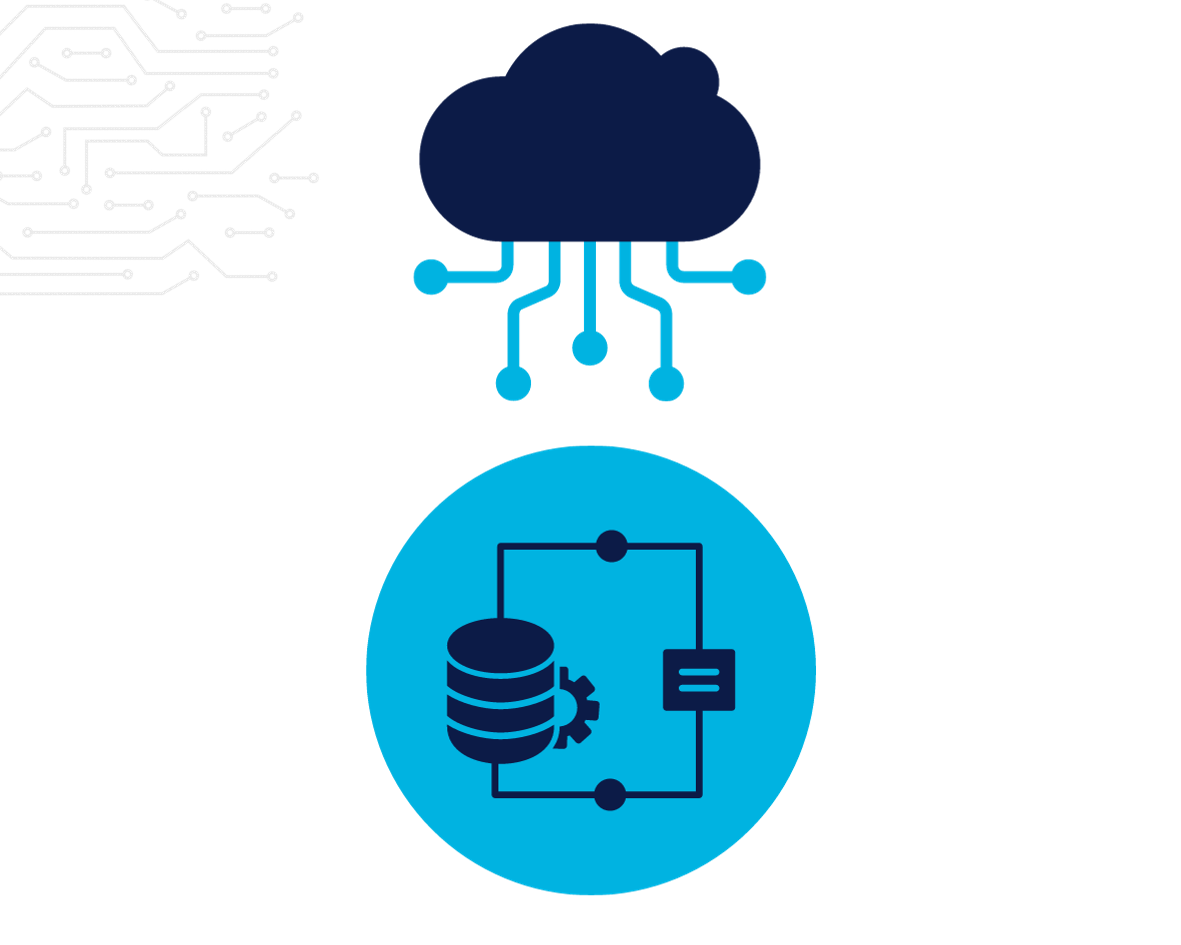

Integration of IT and OT systems

There are a wide range of benefits of using automation in manufacturing. Integration with Visual Factory and your company’s manufacturing ERP system and other IT business services is easy. Visual Factory can automatically synchronize with BOM structures, Parts lists, manufacturing orders that are commonly hosted in manufacturing ERP systems. Similarly, Visual Factory can update data in the IT system with order status, manufacturing data and labour hours to further help improve manufacturing efficiency.

Seamless Integration with IoT Hardware

Visual Factory can seamlessly integrate with shop floor equipment using industry standards such as MQTT. Many industrial hardware vendors now support MQTT to transmit data between hardware and software applications. For example, Visual Factory can read MQTT data from a hardware device to stream the data into a Visual Factory. If a digital work instruction requires a specific setting for the torque wrench, Visual Factory can automatically check the values being published and record it in the database.

This seamless integration removes the requirement for manual verification by the operator resulting in better manufacturing efficiency and fewer chances for error.

NoMuda MES Deployment

Customers can select two options for deploying Visual Factory:

- NoMuda hosts Visual Factory Managed Service for customers that want to rely upon NoMuda to run their instance of Visual Factory. This allows our customers to focus on being experts in their shop floor processes and rely upon Nomuda to ensure Visual Factory is always available and up to date. Visual Factory Managed Service is hosted on AWS or Azure.

- Visual Factory self hosted allows our customers to operate VisualFactory in their own data center.

Our Accreditations

Copyright © 2024 NoMuda. All rights reserved.