Empowering Operators with Integrated MES Software

A Manufacturing Execution System (MES) bridges the gap between ERP and the shop floor – enabling real time visibility, control, and standardization across your production environment. By capturing and delivering the data needed to manage day to day production lines, NoMuda’s VisualFactory ensures operators have the right information, at the right time, in the right places.

Solving Your Biggest Production Challenges

Disconnected Systems

Eliminate gaps between ERP and shop floor systems with seamless digital workflows and visual aids.

Inconsistent Processes

Standardize operator guidance, even in variant rich production lines, and reduce reliance on tribal knowledge.

Poor Traceability

Track every part, action, and process in real time – ensuring verification and compliance from operator to output.

Inefficient Tools

Connect shopfloor tools to VisualFactory and let operators focus on quality rather than data entry.

A Smart MES for Smarter Operations

Built For Lean and High Mix Manufacturing

NoMuda’s MES is engineered to support operators working in environments with configurable products and flexible production processes. VisualFactory improves consistency through validated processes, automated version control, and embedded approvals.

Seamless ERP Integration

A smooth integration between ERP and MES solutions increases planning and scheduling, data visibility, and overall operational efficiency. VisualFactory eliminates data silos and reduces reliance on manual entry by synchronizing production data across business operation systems.

Streamline Quality and Compliance

Automatically captures detailed records for full, seamless, traceability and compliance as standard. With VisualFactory, you get built in digital documentation meant for the strictest industry and regulatory standards.

Human Centric Design

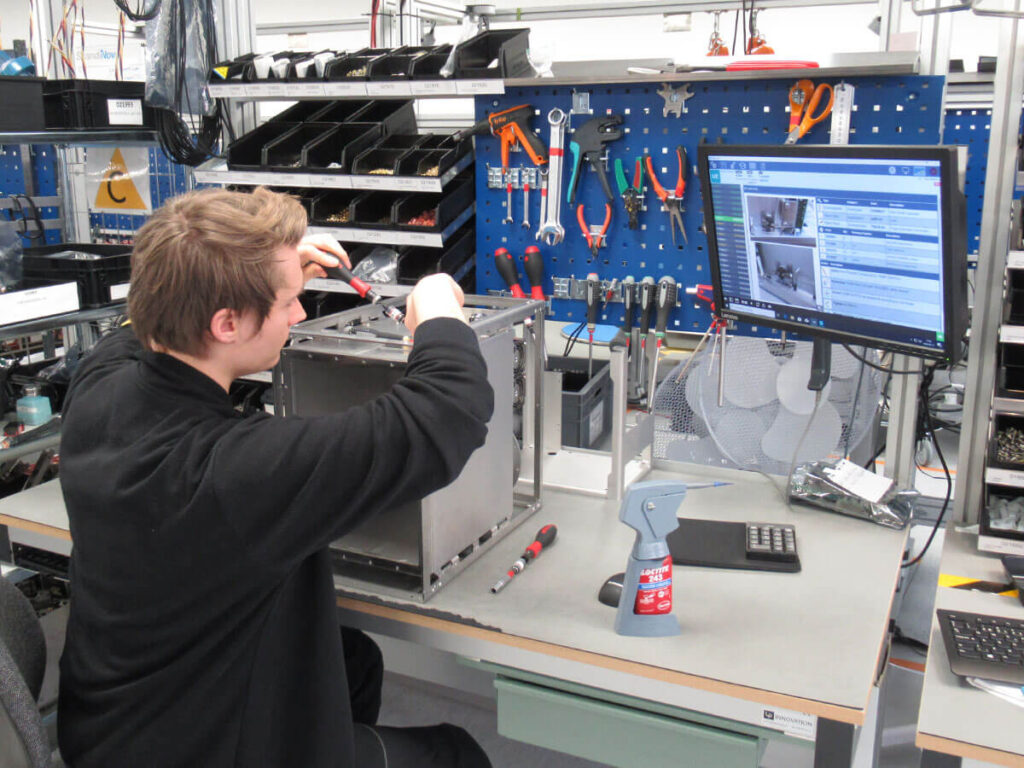

Empower your people – not just your machines – to perform better, faster, safer, and with less waste. VisualFactory’s intuitive interface guides operators step by step, acting as a digital companion at every stage of the production line.

How MES Connects your Operations

Receive Work Order from ERP

Pull production orders and part configurations from your ERP or planning system.

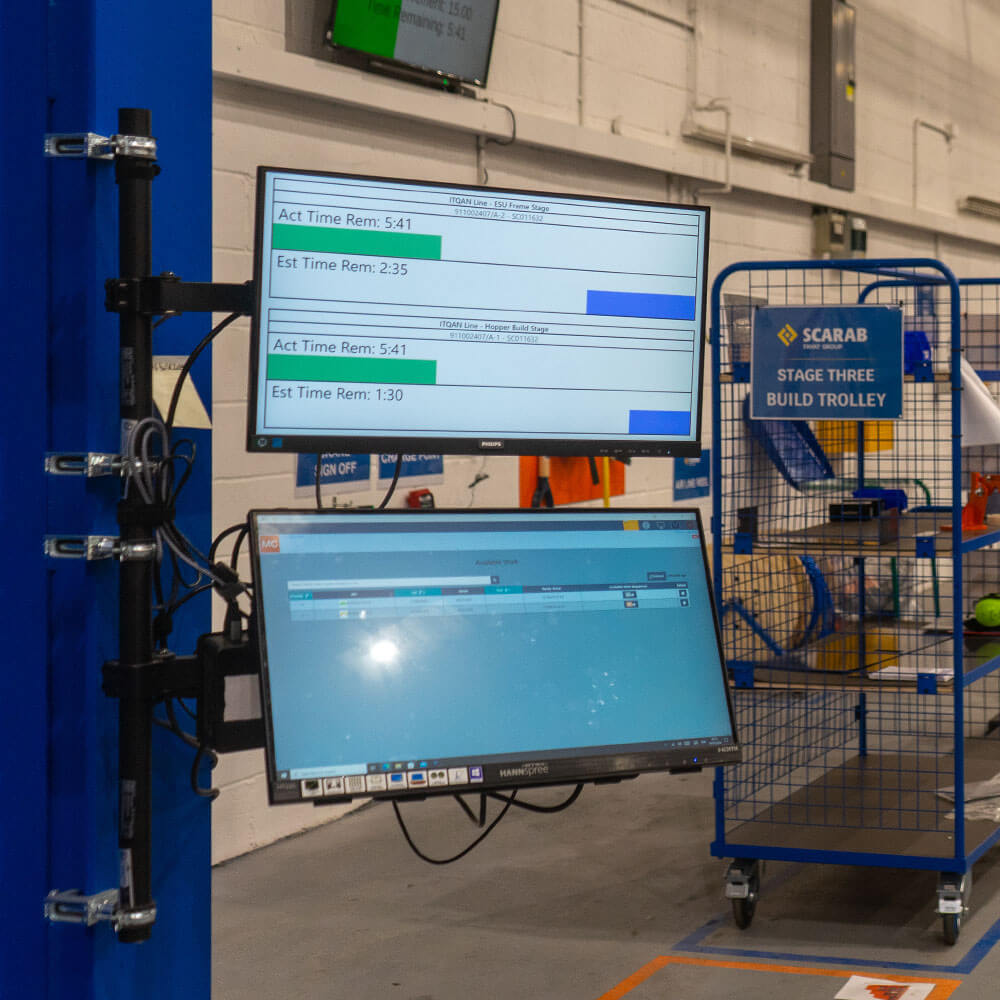

Guide Work on the Shop Floor

Deliver step by step instructions, quality checks, and verifications to operators.

Capture and Verify Data

Record production activity, inspections, serial numbers, and digital sign offs in real time.

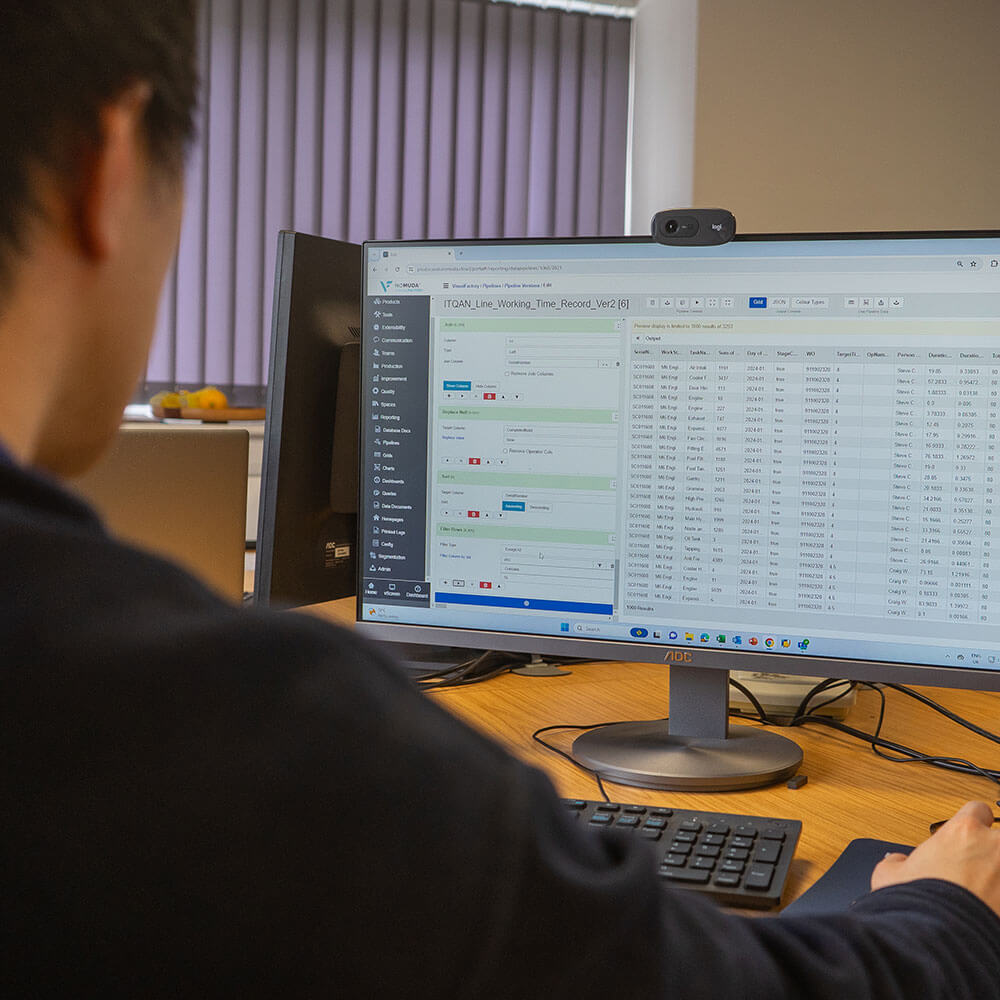

Feedback and Reporting

Send validated data back to ERP and dashboards for live operational insight.

Why Manufacturers Choose VisualFactory as Their MES Solution

Reduce Waste

Enable operators to eliminate errors, downtime, and overproduction to increase areas like paper savings and scrap reduction.

Accelerate Onboarding and Training

New operators can learn skills and execution processes faster with interactive, intuitive directions.

Improve Right First Time Rates

Standardized processes and built in checks mean fewer mistakes and reduced risk of rework scenarios.

Enable Continuous Improvement

Access the data you need to identify trends, root causes, and areas of opportunity for Kaizen.

Partnering with Leaders in

Aerospace & Defense

Ensure compliance with aerospace and defense requirements, like AS9100 and ITAR.

Aerospace & Defence

Automotive & Transport

Enhance automotive and transport delivery performance, with intuitive dashboards that effectively measure OEE.

Automotive & Transport

Consumer Products

Scale confidence and enhance product launches with paperless instructions and integrated quality checks.

Consumer Products

High Tech & Electronics

Improve compliance, scale precision and agility and maintain end‑to‑end traceability for high tech electronics.

High Tech & Electronics

Industrial Products

Transform industrial production with a solution designed for complexity, performance and real time visibility.

Industrial Products

Medical Device Manufacturing

Build safe and compliant products that meet FDA and ISO requirements, with skill validations and audit trails.

Medical Device Manufacturing

Pharmaceutical Manufacturing

Digitize pharmaceutical batch production with a program that supports compliance on the floor.

Pharmaceutical Manufacturing

What Clients Say About VisualFactory

Case Studies

Frencken

Frencken Mechatronics’ production team needed an MES that was going to provide them with full traceability to ensure that their medical products satisfy FDA guidelines.

Read more

Hensoldt

HENSOLDT UK – a world leader in maritime navigation. VisualFactory has enabled greater control over their shop floor process, improving manufacturing efficiency.

Read more

Ravo Fayat

A leading manufacturer of street sweepers manages the production process of their highly complicated product with VisualFactory giving them right first time quality.

Read more